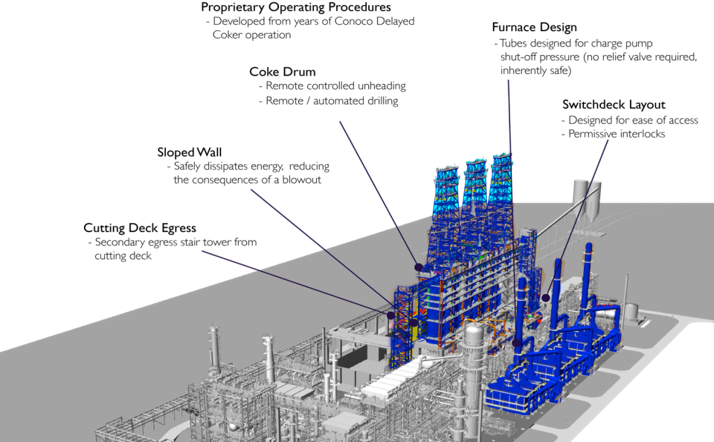

ThruPlusSM is a premier delayed coking technology—the industry’s leading choice for converting heavier oils into high-value products. With our unequaled operational stream factors and patented proprietary process, we can achieve the lowest coke yields and the highest high-value liquid yields in the industry. The ThruPlusSM coking process delivers a cost-effective potential for petrochemical integration and higher value coke outlet configurations.

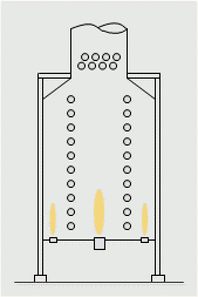

ThruPlus® Feature: Modified Double Fired Furnace

- Proprietary, empirical furnace design simulation and methodology predicts tube-by-tube conditions and pressure drops to allow tailoring of the design to minimize fouling and maximize run lengths.

- Design uses state-of-the-art CFD fireside modeling to optimize burner design for the best possible flux profile.

- Configuration enhances on-line spalling effectiveness and facilitates pigging, minimizing throughput loss and maximizing intervals between decokes.

- Proprietary radiant section cast return bend designed to withstand erosion from on-line spalling.

- Furnace tubes and transfer line designed for blocked-in pump shutoff or steam pressure eliminates need for transfer line relief valves and achieves excellent creep life.

- Use of ceramic fiber refractory minimizes likelihood of coking up on loss of flow.

- Requires less plot space and has a lower cost than other double fired designs while providing the same benefits.

- Minimum Furnace Emissions: BETS furnace design provides lowest practical emissions with fuel gas with Ultra-Lo NOx burners having >91% efficiency.

ThruPlus® coking delivers potential for petchem integration and higher value coke outlet configurations

Learn more about Bechtel Energy Technologies & Solutions.